The Future of Food Technology: Robotics and Automation in Food Manufacturing and Processing

Implementing robotics and automation in the food manufacturing industry poses several challenges that need to be carefully addressed. One major obstacle is the high initial cost involved in integrating robotic systems into existing production lines. Companies must make large investments in purchasing, installing, and maintaining robots, which can be a significant financial burden.

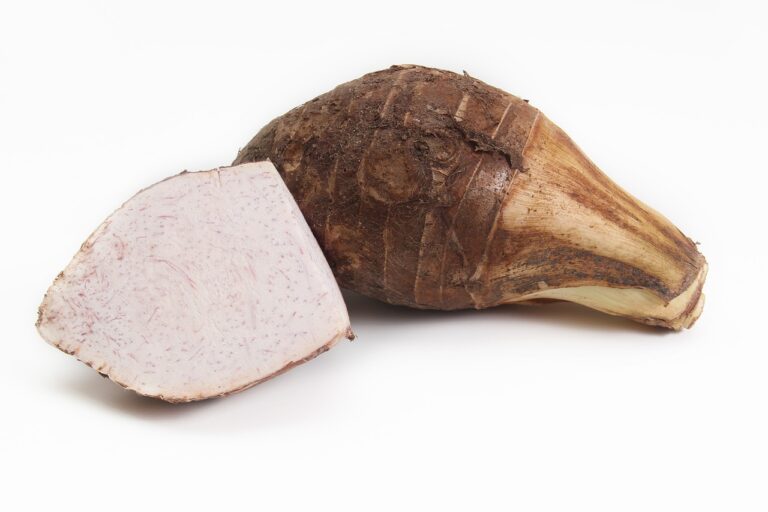

Another challenge is the complexity of food processing tasks, which can vary greatly depending on the type of product being manufactured. Unlike in other industries where tasks are more standardized, food processing often involves handling delicate materials, following strict safety regulations, and adapting to changes in ingredients or recipes. This variability makes it challenging to develop robotic systems that are versatile enough to handle the diverse requirements of food manufacturing processes.

Benefits of Incorporating Robots in Food Processing

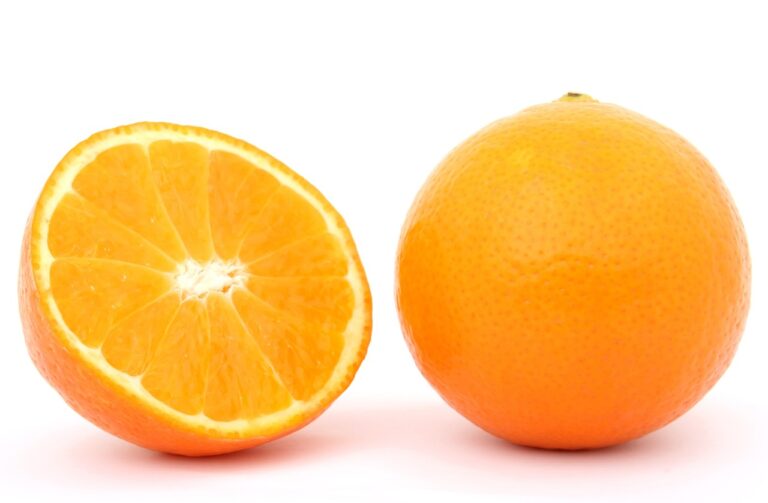

Robots in food processing bring numerous benefits to the table. Their high precision and consistency ensure uniformity in tasks such as cutting, packaging, and sorting, leading to improved product quality. Robots can handle repetitive and mundane tasks with ease, allowing human workers to focus on more strategic and creative aspects of food production. This not only enhances overall efficiency but also reduces the risk of human errors, ultimately leading to cost savings for food manufacturers.

Another advantage of incorporating robots in food processing is their ability to enhance food safety standards. By minimizing direct human contact with food products, robots help prevent contamination and ensure compliance with strict hygiene regulations. Additionally, robots can operate in controlled environments, reducing the risk of foodborne illnesses and enhancing the overall safety of the manufacturing process. This increased level of safety not only benefits consumers by providing them with safe and high-quality food products but also protects the reputation and credibility of food manufacturers.

Current Trends in Robotics and Automation in the Food Industry

Advancements in technology have paved the way for robots to handle intricate tasks in food processing plants, leading to improved efficiency and accuracy. In recent years, collaborative robots or “cobots” have gained popularity in the food industry due to their ability to work alongside human operators to enhance productivity and safety.

Moreover, the integration of artificial intelligence and machine learning in robotics has enabled machines to adapt to changing conditions, optimize production processes, and perform complex tasks with minimal human intervention. As a result, food manufacturers are increasingly turning to automated solutions to streamline operations, reduce costs, and meet the growing demands of consumers for high-quality products.

What are some challenges in implementing robotics and automation in food manufacturing?

Some challenges include high initial costs, the need for specialized training for employees, concerns about food safety and hygiene, and the potential for job displacement.

What are some benefits of incorporating robots in food processing?

Some benefits include increased efficiency and productivity, improved consistency and quality of products, reduced labor costs, enhanced food safety measures, and the ability to handle repetitive or dangerous tasks.

What are some current trends in robotics and automation in the food industry?

Some current trends include the use of collaborative robots (cobots) that work alongside human employees, the implementation of autonomous mobile robots for material handling and logistics, the adoption of automated packaging and labeling systems, and the integration of artificial intelligence for predictive maintenance and quality control.